Dies and Rollers

Flat die of pellet machine and rollers of pellet mill are the core and wearing parts, their quality directly affects productivity effect and the work life of pellet machine. When buying a pellet machine, the spare parts are very important, especially flat die and roller. GEMCO can supply customers with high quality flat dies and rollers for flat die pellet machine.

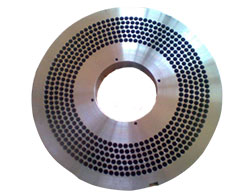

Flat die

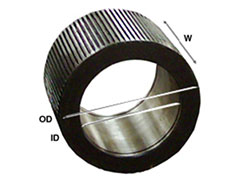

Roller

Flat die of pellet machine

- Model: 150, 200, 230, 260, 300,400 type

- Power: single-phase 2.2 kw, triple-phase 3-30 kw

- Capacity: 40-800 KG/H

- Size of flat die: 2-10 mm

Brief introduction of pellet machine flat die

The shape of pellet machine flat die is discoid and many holes spread on it. The cylinder shape of final pellets are formed through these holes. The diameter of holes is from 2mm to 10mm, they are manufactured according to your specific raw material to make sure best yield of your pellets. In GEMCO, you will have one customized pellet machine flat die for one kind of raw material.

Process of GEMCO pellet machine flat die

GEMCO pellet machine flat dies are processed through 6 procedures including forge, reaming and polish. Adopting 40Cr and processed by special heat treatment, so our flat dies are more wear-resistant, smoother and have higher hardness. GEMCO have the most advanced drilling machine, which can process flat die with more accurate positioning and higher efficiency. If your accessories wear out, you’d better buy original spare parts. We supply you with high quality flat dies at any time.

Advantages of GEMCO pellet machine flat die

- Pellet machine flat dies are made from precise material of alloy metal which makes this core part wear-resistant and not easy to break. Both sides of the die can be used, so the service life can be prolonged.

- The service life of GEMCO flat die can up to 800 hours.

- Quick disassembling type precisely-cast die clamp is adopted to connect the die and quill flange, you can change new die fast and conveniently according to your needs.

- Our factory can produce and supply different aperture sizes of flat die according to your requirement.

- GEMCO pellet machine flat dies have the best compression ratio for more than 30 kinds of raw materials, which can ensure the quality of final pellets.

Rollers of pellet mill

- Model: 150, 200, 230, 260, 300 type

- Power: 10-41 HP

- Capacity: 40-800 KG/H

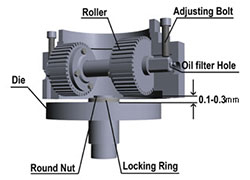

Brief introduction of pellet mill rollers

Usually, pellet mill rollers are covered with steel shells, they have high stiffness and rough surface, so which can ensure the strength of the extrusion. In the process of pellets production, the friction between the rollers and the die is frequent, so they are easy to wear. Big diameter rollers have more higher output capacity, the made pellets have more higher molding rate, more higher hardness and more homogeneous size.

Working Principle of pellet mill rollers

Pellet mills have D-type and R-type, the differences are the rollers. Rollers are important parts of pellet mills, which also have D type and R type. D type is rotating die type, which means the roller is fixed and the flat die is rotating with the main shaft. On the contrary, R type is rotating roller type, it means the roller is rotating with the main shaft and the flat die is fixed. When the pellet mill works, the raw materials are pressed by the roller and flat die, then become the shape of strips and emerge on the other side of the die, the blade cut them into the same length finally.

D type

R type

Advantages of GEMCO pellet mill rollers

- GEMCO pellet mill rollers are made of high quality alloy steel, which have good granulating effect, high output and long work life.

- Our pellet mill rollers adopt 40Cr and are processed by special heat treatment, so they are more wear-resistant, smoother and have high hardness.

- Design structure of pellet mill roller is reasonable, which makes running more smoothly and lubrication better.

- The lifespan of our pellet mill rollers can up to 1000 hours, and we have ISO9001 and CE international certification. If your pellet mil roller wears out, you can purchase original spare parts from us.

- We can process different sizes of rollers according to customers’ needs.

- We offer good pre-sale and after-sale service, and you can contact us at anytime.

How to maintain flat dies and rollers?

Before working, you should check the die and roller of pellet machine for ensuring that no foreign body on the surface and no wear. After a period of time, the flat die of pellet machine should be turned to the other side, especially a thin die. When the both sides of die are not good to use or the made pellets are not hard, you need to change a new die. Generally, you can replace the press mill rolls together when replacing the new die. Welcome to contact us freely!

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within 24 hours. Please feel FREE to contact us!