Integrated Mobile Pellet Plant

Introduction of integrated pellet plant

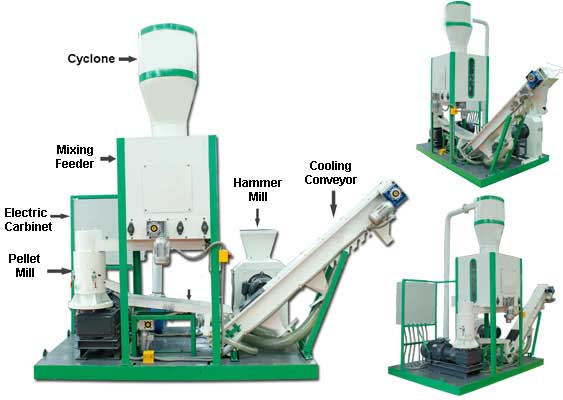

Integrated pellet plant is an integrated system, also called small pellet plant, is our new small pellet production plant. It is with pellet mill and other supporting equipments which highly efficient in making biomass or animal feed pellets. It blends the advanced technology of home and abroad.

This integrated pellet plant includes all necessary equipments, such as hammer mill, separation system, pneumatic handing system, mixture feeder, tempering system, facility for pelletizing, cooling system, conveying mechanism and etc. to integrate the functions of crushing, pelletizing, cooling, transporting and etc into one plant, which lowers your cost and improves working efficiency. And all of its necessary processing parts are on one base, which makes it easy to move to anywhere. Now we have produced the MPL300 and MPL400 with capacity of 250-350/350-450kg/h for your choice. The raw materials can be saw dust, straw, crop waste, feed mixtures, wood , chips and etc.

The integrated pellet plant is concise in exterior design, and adopts variable frequency regulation to control the key workflow which can meet different requirements of our customers. The finished pellets are very smooth and have high density and delicate surface.

Composition of mobile pellet plant

This new integrated pellet plant contains the whole equipments which can process raw materials from the very beginning to the final pellets. They mainly contain hammer mill, separation system, pneumatic handing system, mixture feeder, tempering system, facility for pelletizing, cooling system, conveying mechanism and etc. And all these equipments combine the functions of crushing, pelletizing, transporting, cooling and etc into together, which makes it easy to make pellets and lower the cost improve the working efficiency.

Hammer mill

Vibrating sieve

Storage bin

Pellet mill

Application of integrated pellet plant

This integrated pellet plant can be used biomass materials of sawdust, straw, stalk, waste wood chips, waste pieces, tree branches, peanut shell, sunflower husk, grass, wood shaving and so on.

The pellets made by integrated pellet plant can widely used as biofuel and household energy consumption with high combustion ratio and easy to store. What’s more, it can be used in the industrial boiler and the thermal power generation, instead of coal as the main fuel to solve the problem of pollution. In addition, can be used in aquaculture, feed mill, livestock farm, poultry farm etc.

Advantages of integrated pellet plant

It’s flexible to move compared traditional pellet plant. It has small size. Mainly about 3.5*2*3.5m³.

It integrates all the functions together, such crushing, pelletizing, cooling and conveying processes. Which can save money and improve output.

It applies high quality materials. All the equipments are made of high steel alloy and other high quality materials.

Specifications of integrated pellet plant

| Model | Capacity(kg/h) | Pellet Diameter(mm) | Power(kw) | Size(mm) |

|---|---|---|---|---|

| MPL300 | 250-350 | 6-12 | 41.25 | 3500*1960*3500 |

| MPL400 | 350-450 | 6-12 | 49.25 | 3500*1960*3500 |

We can also offer complete pellet production line for your choice.